Overview

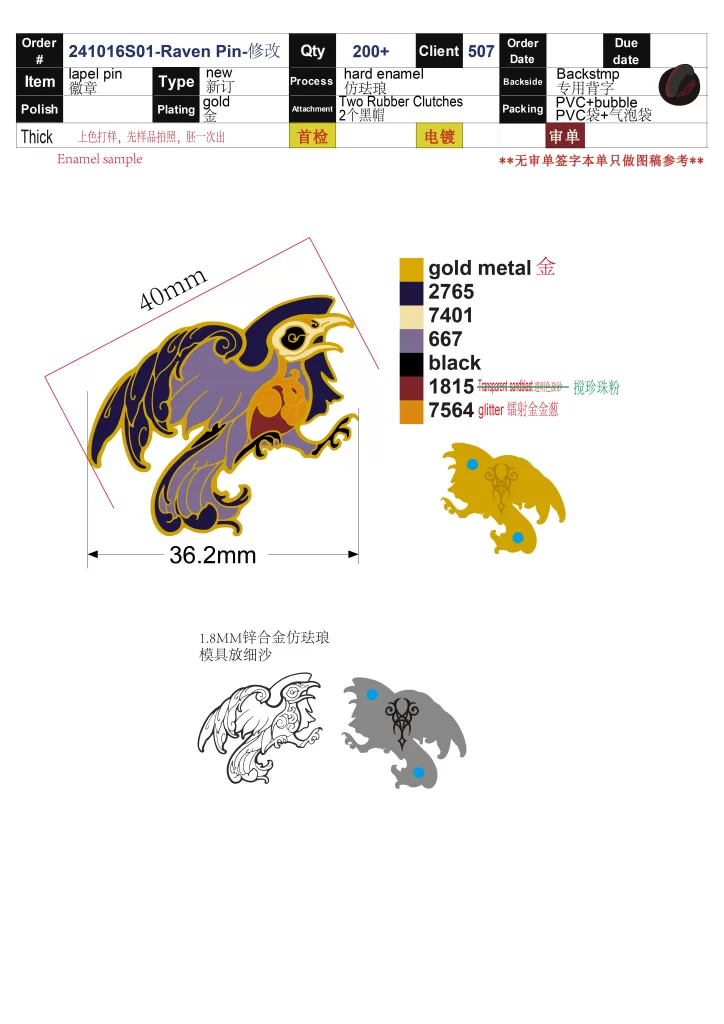

This case study highlights the design and production process behind a custom hard enamel Raven Pin, a meticulously crafted collectible featuring intricate details, elegant gothic aesthetics, and a polished gold-plated finish. The size of this raven pin is 40mm. Deep, rich colors and fine-line engravings emphasize the mythical and majestic nature of the raven.

The project involved multiple design revisions, precise enamel color selection, and high-quality craftsmanship to ensure a final product that met the client’s expectations. From the initial sketch to the final pin, every step was handled with precision to create a stunning enamel accessory that is both durable and visually striking.

Pin Design Details

- A detailed raven design with feathers and linework to give the piece a mystical and regal feel.

- Hard enamel process to ensure a smooth surface that is both durable and long-lasting.

- Gold plating to enhance the intricate details and give the pin a luxurious finish.

- Pantone color matching, with carefully selected shades, such as deep purples, black, and so on

- Glitter enamel accents to highlight specific areas and add a touch of shimmer.

- Pearls

- Size: 40mm

- Two rubber clutches to provide a secure and comfortable attachment.

- Packaging: Pvc bag+Bubble bag

Design & Main Production Process

1. Concept Development & Initial Design

The project started with a original design. This initial design captured the general shape, proportions, and flow of the raven’s feathers. Special attention was given to the wings, ensuring that the details conveyed movement and elegance. The design also featured a fierce expression, symbolizing power and mystery.

2. Digital Vectorization & Color Selection

The designer would arrange the artwork according the client’s original design and requirements. This step refined the linework and made the design production-ready. During this phase, specific Pantone colors were selected to ensure consistency in the final enamel application.

The chosen colors included:

- Pantone 2765 (Dark Purple) – for the main body of the raven, adding depth and a mysterious aura.

- Pantone 7401 (Light Yellow) – for highlights, creating contrast and adding dimension.

- Pantone 667 (Muted Blue-Purple) – used for subtle shading effects.

- Black Enamel – defining the intricate details and enhancing contrast.

- Pantone 1815 (Deep Red) +Pearls– providing a bold accent on the chest area.

- Glitter Enamel (Pantone 7564) – strategically applied to certain elements to make the pin stand out under light.

3. Metal Molding

Once the digital design was finalized, a 1.8mm thick zinc alloy mold was created. The mold was precision-cut to ensure every feather and swirl was accurately represented.

4. Enamel Filling

With the metal base complete, the next step was enamel filling.

- Each section of the pin was carefully hand-filled with the chosen enamel colors.

- The raven pins were baked at high temperatures to cure the enamel, ensuring a hardened, glossy surface.

5. Wet Grinding & Polishing

- Wet grinding could make the metal lines on the pin visible.

- The raven pins went through a polishing process, giving them a smooth, glass-like finish.

6. Plating

The raven pins were plated in gold, which added durability and gave the final product a premium finish.

5. Quality Control

Before shipping, each raven pin underwent a rigorous quality inspection to check for imperfections.

Each finished pin was then individually packaged with pvc bag and bubble bag to prevent scratches during transit.

Final Product & Client Feedback

The final Raven Pin successfully captured the intricate details of the original design. The deep purple and black enamel contrast beautifully with the gold plating, while the glitter accents add a subtle shimmer, making the pin stand out. The smooth hard enamel surface ensures longevity, while the fine details in the engraving reflect the craftsmanship put into its creation. The pearl effect is also great!

The client was extremely satisfied with the final product and shared their feedback:

“The craftsmanship is incredible! The colors turned out exactly as we envisioned, and the gold plating makes every detail pop. The glitter effect and pearl effect are beautiful, and the overall quality exceeds our expectations. We can’t wait to create more designs with you!”

This case study demonstrates the dedication and expertise required to produce high-quality custom enamel pins that exceed client expectations.

Looking to Create Your Own Custom Pins?

If you’re looking for a manufacturer who can bring your custom enamel pin designs to life with expert craftsmanship, attention to detail, and premium materials, we are here to help!

Contact us today to start your next pin project!