This case study explores the full development process of the “Couple in Poppies” custom 3D hard enamel pin, a premium collectible designed with complex layered artwork, gold-plated metalwork, selective pearl effects, and precision UV printing. The project highlights how detailed illustration, multi-step manufacturing, and coordinated material planning can come together to create a highly artistic enamel pin suitable for high-end collectors and limited-edition releases.

Project Overview

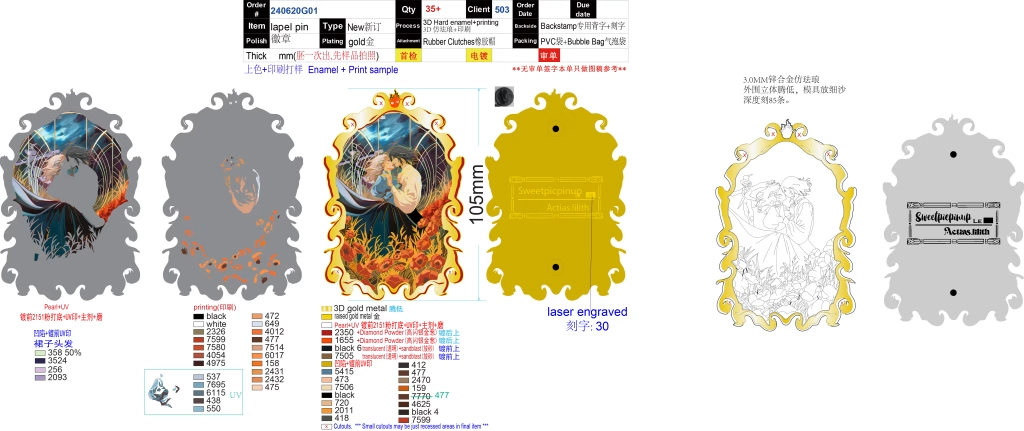

The “Couple in Poppies” pin was developed as a large, visually immersive art piece. The final size measures 105 mm in height, which is significantly larger than standard enamel pins. This expanded format allows both the frame and the central artwork to feature rich details. The design incorporates a 3.0 mm thick base, raised 3D metal contours, and an ornate Victorian-inspired frame. Metal areas are plated in polished gold, enhancing the visual contrast with the vibrant enamel and printed details.

The front of the pin showcases an intimate scene of two characters embraced against a luminous sky and surrounded by flowing poppies. The illustration includes both warm and cool tones, intentionally layered to create depth, movement, and a soft, romantic atmosphere. To ensure the artwork transferred accurately to metal, the design required coordinated application of pearl enamel, translucent enamel, and UV printing.

The back side includes a custom laser-engraved backstamp with branding information. Rubber clutch attachments were selected for comfortable and secure display.

Manufacturing Breakdown

1. 3D Metal Structure and Mold Creation

The initial step involved sculpting a raised metal mold with varied depths. The frame required sculpting with curves, curls, and ornamental edges, while small recessed zones were added to lock printed layers in place. The mold depth reached 85 degrees in selected areas to emphasize dimensionality. This sculpted relief forms the foundation for all subsequent color applications.

2. Gold Plating and Base Finish

Once the mold was finalized, the pin was cast in alloy and polished. A gold plating was applied to enhance the luxurious theme of the artwork. The finish required fine preparation because any imperfections would become highly visible once translucent enamel and pearl layers were added.

3. Hard Enamel Color Filling

The design uses several categories of enamel:

- Standard Hard Enamel: For solid, opaque colors in character clothing and hair.

- Pearl Enamel: To create soft, shimmering areas such as the flowing fabric and sky.

- Translucent Enamel: Used strategically over textured metal to generate depth in the underwater-like blue gradients.

Multiple color codes were defined for accurate mixing. Each enamel layer was added and polished to ensure a completely flat surface before UV printing.

4. UV Printing and Gradient Detailing

A key highlight of this product is the integration of UV printing atop the enamel surface. The printed sections include gradients, soft shadows, fine linework, and reflective highlights. These details are essential for capturing the emotional intensity of the original illustration, especially in the characters’ faces, hair, and background lighting. The design file separates printing areas precisely so the manufacturer can register each layer without smudging or misalignment.

For certain printed elements, additional diamond powder and sandblast textures were applied beneath colors to enhance the glow and depth.

5. Laser-Engraved Backstamp

The backside of the pin includes a custom engraving featuring the brand name and edition information. The engraving depth was set to 30 for clarity while maintaining a smooth metal finish. This backstamp confirms authenticity and maintains consistency across the artist’s product line.

6. Finishing and Assembly

After final printing, the pin underwent surface coating and inspection. Rubber clutches were selected because they offer secure attachment without scratching the metal plating. The final product was packed in protective PVC and bubble bags to prevent damage during shipping.

Artistic Interpretation and Design Complexity

The “Couple in Poppies” pin is a strong example of combining illustration with metal craftsmanship. The frame acts as both a functional border and an artistic accent, supporting the romantic and dreamy tone of the artwork. The characters are illustrated in soft, flowing lines, contrasting with the sharp, crisp edges of the ornamental border.

One of the most notable challenges in this project was harmonizing the vivid gradient sky, the warm tones of the poppies, and the intricate small elements without losing clarity when scaled to enamel pin format. The use of pearl and translucent effects gives the artwork an almost illuminated appearance, allowing light to interact with the surface in subtle ways that mimic the original digital illustration.

Developing a large-scale enamel pin of this type requires balancing printing precision with enamel placement, ensuring the artwork retains its emotional resonance while meeting manufacturing limits. The final result demonstrates how a detailed concept can be translated into a durable, collectible piece of art.

Frequently Asked Questions (FAQ)

1. Why was hard enamel chosen instead of soft enamel?

Hard enamel provides a smoother, more polished finish that matches the elegant aesthetic of the design. It is also better suited for UV printing and pearl effects.

2. What makes 3D metal sculpting important for this pin?

The raised frame and recessed zones enhance the visual depth of the artwork, especially when paired with translucent enamel. Sculpting allows the metal itself to contribute to the final visual effect.

3. How does UV printing improve the design?

UV printing captures fine details such as facial features, subtle gradients, and lighting effects that cannot be replicated with enamel alone. It preserves the accuracy of the original illustration.

4. Why was gold plating selected?

Gold plating emphasizes the ornate frame and elevates the pin to a premium collectible category. It also complements the warm tones of the poppy flowers in the artwork.

5. Can this production method be applied to smaller pins?

Yes, but certain details may need adjustment. Larger pins allow for more detailed linework and complex color transitions.

Conclusion

The “Couple in Poppies” custom enamel pin is an excellent representation of how detailed illustration and advanced manufacturing can combine to create a collectible art piece. Through the use of 3D sculpting, hard enamel finishing, pearl and translucent effects, and precision UV printing, the final product brings out the emotional depth of the original artwork while maintaining durability and display value.

This case demonstrates the importance of thoughtful material selection, careful layer planning, and collaboration between artist and manufacturer. The final result is a sophisticated and visually compelling enamel pin that stands out as both a functional item and an artistic keepsake.